HHL SHOWERSTEADY

SUMMARY:

ShowerSteady is a modular and adaptable grab bar structure for an alcove bathtub/shower. Installing a single grab bar in the shower area often requires expensive and extensive bathroom renovations. This is because fiberglass/acrylic inserts are often ripped out and replaced to assess the wall integrity behind them. Our team’s solution, ShowerSteady, is a grab bar structure contained inside the shower area that is mounted to the wall above the shower insert and compression fit to the floor. Horizontal, multilevel, or other types of grab bars can be mounted at any desired height for a user onsite. Additionally, the grab bars are multi-purpose—acting both as stable grabbing points and for mounting additional fixtures. All grab bars and attachments are easily adjustable so the structure can be tailored to multiple users of a single shower, or for the changing needs of one user over time.

TIMELINE:

-

I have guided the development of ShowerSteady with the HHL team from inception in September 2023 to present day.

PROJECT TEAM:

PROJECT LEAD:

SKILLS LEARNED/UTILIZED: Brainstorming and ideation sessions; illustration and rendering; fabrication of prototypes using power tools, CNC mill, plasma cutter, and tubing bender; test plan and protocol development; testing rig creation and testing conduction; IP Development; focus group preparation and data synthesis; prototype field trial preparation, conduction, and qualitative interviewing.

MY CONTRIBUTIONS TO DEVELOPMENT

Ideation and Concept Rendering

September 2023 - August 2024

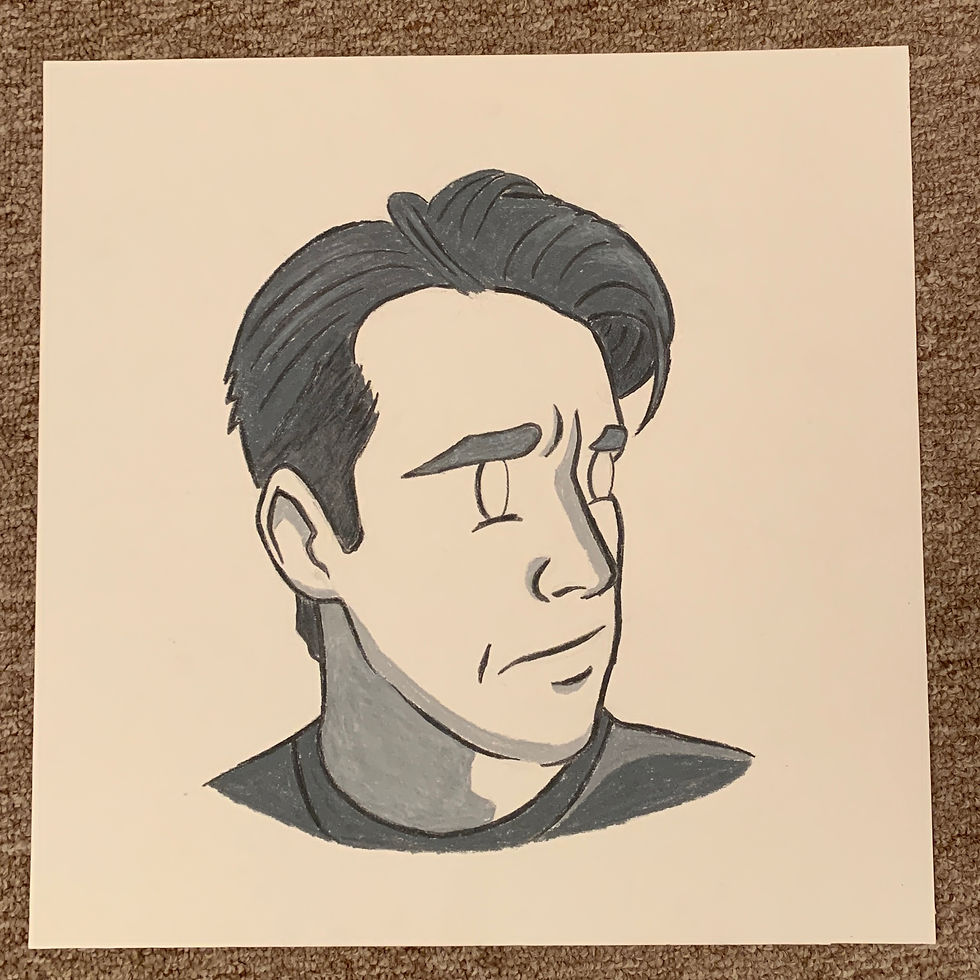

The idea emerged from HHL team member, Todd Hargroder, who envisioned an exoskeleton structure in a shower to mount grab bars, tub chairs, and other attachments to for bathing. Using this concept, I created various early-stage renderings (Images 1-3) of what would become ShowerSteady.

In the renderings, ShowerSteady would focus on being a modular grab bar structure that would be mounted above the shower insert. In addition to acting as grab bars, the tubing could as as a secure mounting surface by accommodating various attachments, such as a tub bench, soap holder, W-shaped grab bar, etc.

These concepts were presented and evaluated with HHL’s commercial partner, Vest Inc—a home therapy service of OTs that provide dozens of home visits per month. They acted as our clinical team, helping steer the direction of the concept that addressed a lot of the mobility issues their clients would face while bathing. Multiple versions were evaluated by the clinical team (Image 2-3), but the final ideated prototype was shown in Image 1.

This was the final illustration of a potential ShowerSteady structure layout during our teams ideation phase. Using a rail mounting system above the shower insert was finalized, Tensioning the front poles to the floor was determined. An initial suite of attachments was determined as well with guidance from the clinical team.

This layout was next, as it added mounting rails above the insert instead of directly screwing into the wall. Any clamps or using the tub edge to support weight/force were changed in favor of tensioning the front posts directly to the floor. Here, there was consideration of a padded tub edge cover to stabilize the the structure by preventing inward rotation. This design configuration was determined to not be relevant with appropriate tensioning of the front posts.

Static strength testing on early ShowerSteady prototype. This was achieved using a spring scale, car jack, and uni-strut mounted to the subfloor. Early testing was to determine tubing and clamp integrity.

This was the final illustration of a potential ShowerSteady structure layout during our teams ideation phase. Using a rail mounting system above the shower insert was finalized, Tensioning the front poles to the floor was determined. An initial suite of attachments was determined as well with guidance from the clinical team.

From their feedback, I worked with fellow research engineer, Joel Fadness, on building a rough prototype of ShowerSteady in the HHL bathroom out of 1.5” OD bare steel tubing, plywood, and custom 3D-printed tube clamps designed by Joel. I supported Joel on the cutting, assembly, and installation of this early prototype rig (Image 5-6).

Early strength testing on tubing and clamp integrity was conducted using a car jack and a ratchet strap. Successful strength testing results, positive feedback from the clinical team, and awarded grant funding from the VA SAHAT Program validated the need for ShowerSteady and advanced the project out of the ideation stage.

Refined Prototype Design and More Advanced Fabrication

August 2024 - May 2025

This was inspiration for pivoting to connecting all grab bars via simple 1-bolt t-clamps. This streamlined our development and allowed our team to focus on fabricating specialized components instead of making clamps from scratch.

In a mock bathroom stall in our design lab, we tested out various grab bar layout configurations. At this stage, we switched to 1.25" OD aluminum tubing and aluminum t-clamps like the bus stanchions. Here an early mock multi-level grab bar was created. This layout, amongst 4 others, was evaluated by our clinical team.

A winch and digital spring scale were used to perform static strength. At this stage, we were verifying if the switch to smaller diameter aluminum tubing and off-the-shelf t-clamps would still hold up to our 250+ lb loads. Deflection and deformation was measured using a laser measure.

This was inspiration for pivoting to connecting all grab bars via simple 1-bolt t-clamps. This streamlined our development and allowed our team to focus on fabricating specialized components instead of making clamps from scratch.

With grant funding secured, our team set out on brainstorming and constructing a higher resolution prototype. From my illustrations and CAD models created by Paulina, we had several avenues to take for how to mount ShowerSteady in the shower. This included one fully floating above the tub, one having vertical bars resting on the tub edge, and one running vertical tubes directly to the floor. We intended on roughly prototyping each of these variations, conducting strength testing on them to assess structural integrity, and presenting the versions to our clinical team at Vest. As our ideation stage converged on using rails to mount the vertical grab bars, our team utilized our Mobius rail system, another product developed within our lab [see the portfolio page here for more info], increasing the application for that specific project.

At this point in development, we needed a simpler and scalable way to connect grab bars together. On my work commute everyday, I saw various types of clamps used on the stanchions [grab bar structures throughout inside of public transit buses] as shown in Image 1. Inspired by this, we focused on sourcing off-the-shelf aluminum t-clamps for all connections that required a single 6mm Allen key to tighten/adjust per clamp.

In addition to the t-clamps, the main structure composition shifted to 1.25” OD-0.125” thick aluminum tubing which optimized strength, weight, and rust resistance. Using these new materials, we designed several layout configurations to show to our clinical team, one of them is shown in Image 2. We also conducted some static strength testing, now using a winch to create a constant pulling force and a laser measure to monitor deflection/deformation of the tubing under load. With this design passing several static strength tests exceeding 250 lbs, we moved forward with more advanced fabrication of specialized components.

Specialized components such as the w-shaped grab bar, tub chair mounting plate, and jack screw feet required specific fabrication. This work was led by Joel and supported by me. Here, I learned how to use and become proficient with CAM features in Autodesk Fusion360 to generate G-code and operate our plasma cutter [Langmuir Systems CrossFire Pro] and CNC mill [Langmuir Systems MR-1 Gantry Mill] (as shown in Image 2). During this time, I also used chop saws, band saws, and power drills to prep and modify these custom parts. Additionally, I learned with the HHL team how to use a mandrel tubing bender [Rogue Fabrication M600 series with mandrel attachment] to create the multilevel grab bars (as shown in Image 2-3).

In person focus groups where older adults, clinicians, caregivers, and home modifiers in May 2025 as well as field trials involving ShowerSteady to be installed in multiple homes for ~2 weeks at a time required the fabrication of 2-3 ShowerSteady units. During this time, product testing was conducted on the first patch of prototypes fabricated. The ShowerSteady structure we created to be used for product testing, focus groups, and field trials is shown in Image 4.

Here, I am running our automated CNC Mill to create brackets for mounting the tubing structure to the rail above the shower insert.

Here I am operating our tubing bender to create our multilevel grab bars for the ShowerSteady Field Trials.

Here is an image of the fabricated ShowerSteady structure used for focus group evaluations and product testing.

Here, I am running our automated CNC Mill to create brackets for mounting the tubing structure to the rail above the shower insert.

Product Testing

February 2025 - August 2025

Throughout product development, our team would conduct strength testing to verify our design choices. Early strength testing with the car jack in the ideation phase (pre-August 2024) evolved to more comprehensive ISO-based strength tests to determine tubing material and clamp choice (August 2024-January 2025). With the results from these tests verifying the ShowerSteady system was sufficiently strong enough for use of a 250 lb person, our team sought to fully confirm the system would support a 300 lb person. We also sought to determine if ShowerSteady would withstand cyclic loading which simulated an accelerated lifetime of use. This resulted in a more comprehensive suite of both static stability and dynamic durability (cyclic) tests for the entire ShowerSteady structure, including attachments such as a mounted wall-hung tub chair and specialty W-shaped grab bar.

I was in charge of researching relevant standards and drafting all testing plans and protocols for the system. To create these, I cross referenced ISO, ASTM, and ICC standards to determine the max loads, loading positions, and cycle amounts required to satisfy all testing requirements.

The first comprehensive phase of testing in late spring 2025 was focused on worst-case-scenario static strength testing (minimum required number of bars possible) on all grab bars, tub chairs, and attachments in multiple angles and loading positions. This resulted in 60 total tests I was responsible for planning. I also set up the testing rigs for a majority of them, and ran most of them with the HHL team. Static testing of the multilevel grab bar in particular is shown in Image 1.

The second comprehensive phase of testing was a suite of over 20 durability [cycle] tests I planned for the ShowerSteady system—each testing at 3000 cycles (over lifetime usage). I was responsible for setting up around half of these tests and monitoring them. These tests required a testing rig comprised of set up of a scooter motor with an offset protrusion that would pull a cable connected to a weight sled, causing it to raise and lower a weight sled, simulating a 1 second loading cycle. Dynamic cycle testing of the multilevel grab bar in particular is shown in Image 2.

Field Trialing

September 2025 - October 2025

At this stage, strength and durability were verified through product testing and simulated use was validated through focus groups. The next step was to understand actual use conditions. This was completed with a small scale field trial with 4 older adults with mobility limitations in Allegheny County. We used 2 full sets of fabricated ShowerSteady structures that would be cleaned, sanitized, and reused in between users. While Joel was fabricating some duplicate specialized parts, I would assist with CNCing and tube bending.

My primary role during field trials was making sure everything runs smoothly. This included the following tasks:

-

Documenting and cataloguing all the parts, components, and pieces required for each ShowerSteady installation. This included over 100 individual objects.

-

Creating instructions outlining the installation procedure

-

Support HHL team member, Bill Ammer, who led the installs and removals. I would assemble ShowerSteady, take down ShowerSteady, clean and sanitize the structure before use (which I researched and drafted procedures for)

-

Conducted in qualitative post-trial interviews with our PT, Liz Tonarelli, on the test participants to understand their experience using ShowerSteady—brainstorming design improvements and identifying issues

-

Transcribing these post-trial interviews with end users

At the conclusion of the field trials, end user feedback was synthesized and the project was packaged for continuation upon new grant funding.

Note [Jan 2026]: Pending approval on showing photos of ShowerSteady installed in homes. Stay tuned on this.

Current Status

Active and Ongoing. The current version of ShowerSteady is shown here in Image 1. I was involved in all aspects of the development of this device in varying capacities. The bulk of the work was completed over a one year period. In total, our team developed a final prototype that was:

-

Validated by 4 two-week field trials in older adults' homes

-

Verified by over 60 static strength tests and over 20 lifetime cyclic tests

-

A list of feedback and design criteria synthesized through the results of focus groups for over 2 dozen stakeholders. This will be fully implemented in the subsequent grant

We are currently awaiting notice of NIH Direct-to-Phase 2 SBIR grant for continuation of development. This grant would entail larger scale usability studies and field trials, establishing manufacturing partnerships, and making design improvements to various specialized parts, such as a W-shaped grab bar with an easier-to-install multi-part design one shown in one of my renderings in Image 2.

This image of ShowerSteady. This prototype is in a mock plywood shower stall in our testing lab. I overlayed an illustrated bathroom setting for improved aesthetics.

Here is an illustration I created of an improved W-shaped grab bar design that allows for an easier installation.

This image of ShowerSteady. This prototype is in a mock plywood shower stall in our testing lab. I overlayed an illustrated bathroom setting for improved aesthetics.