NEXTGEN-ET DESIGN WORK

SUMMARY:

I worked as a part-time Medical Product Engineer for a University of Pittsburgh research team comprised of engineers, entrepreneurs, and clinicians developing a novel endotracheal tube design (known as NextGenET). This project would subsequently form to become the company, Respair Medical Devices, after my departure in February 2023. During my time in this role, I worked with the team on brainstorming and developing prototypes of a tracheal force testing rig and test protocol. I created educational illustrations of the NextGenET device to easily communicate various design features and their use for various applications. I also led the development of an initial Master Testing Plan and an Initial Harms and Hazards assessment and that would eventually become the Risk Management File to be completed after my departure.

TEAM MEMBERS:

-

Zachary Roy

-

Ross Beresford, MSc

-

Lauren Grice, MSc

-

Garett Craig, MSc

-

Dr. Garrett Coyan

-

Dr. Carl Snyderman

TIME INVOLVED:

-

September 2022 -- Febuary 2023

SKILLS LEARNED:

-

Thorough review of ISO Standards and various FDA Regulatory documents

-

Group Brainstorming

-

Low-Res Prototype Development

-

Verification & Validation Testing

-

Educational Illustration Development

Background on Unmet Need and Novel Design

Prior to my involvement, the NextGenET team discovered from healthcare professional interviews and literature reviews of Infection-related Ventilation-associated Complications (IVACs) that can subsequently lead to Ventilator-Associated Pneumonia (VAP). To paraphrase the research from the NextGenET team:

Prior studies before the Covid-19 pandemic showed that around 300k-400k patients in the US developed an IVAC during ventilator use. Moreover, 1/3 of those who developed an IVAC would subsequently die. Additionally, each ventilator complication costs around $40k which totaled up, adds about $6B to the US Health system annually.

Causes for IVACs and VAP are multifaceted, but clinical feedback showed that the vast majority of current endotracheal tubes (ETTs) use an inflatable barrel cuff (balloon). These balloons can deflate over time, causing wrinkles and openings in the seal that can let bacteria-laden secretions past the cuff and into the lungs and potentially lead to IVACs.

This image from Respair's website visualizes the NextGenET's baffle cuff design and how it helps block secretions from entering the lungs compared to traditional barrel cuff ETTs that either deflated partially or were not properly inflated. Image Credit goes to Respair.

This image from Respair's website visualizes the NextGenET's baffle cuff design and how it helps block secretions from entering the lungs compared to traditional barrel cuff ETTs that either deflated partially or were not properly inflated. Image Credit goes to Respair.

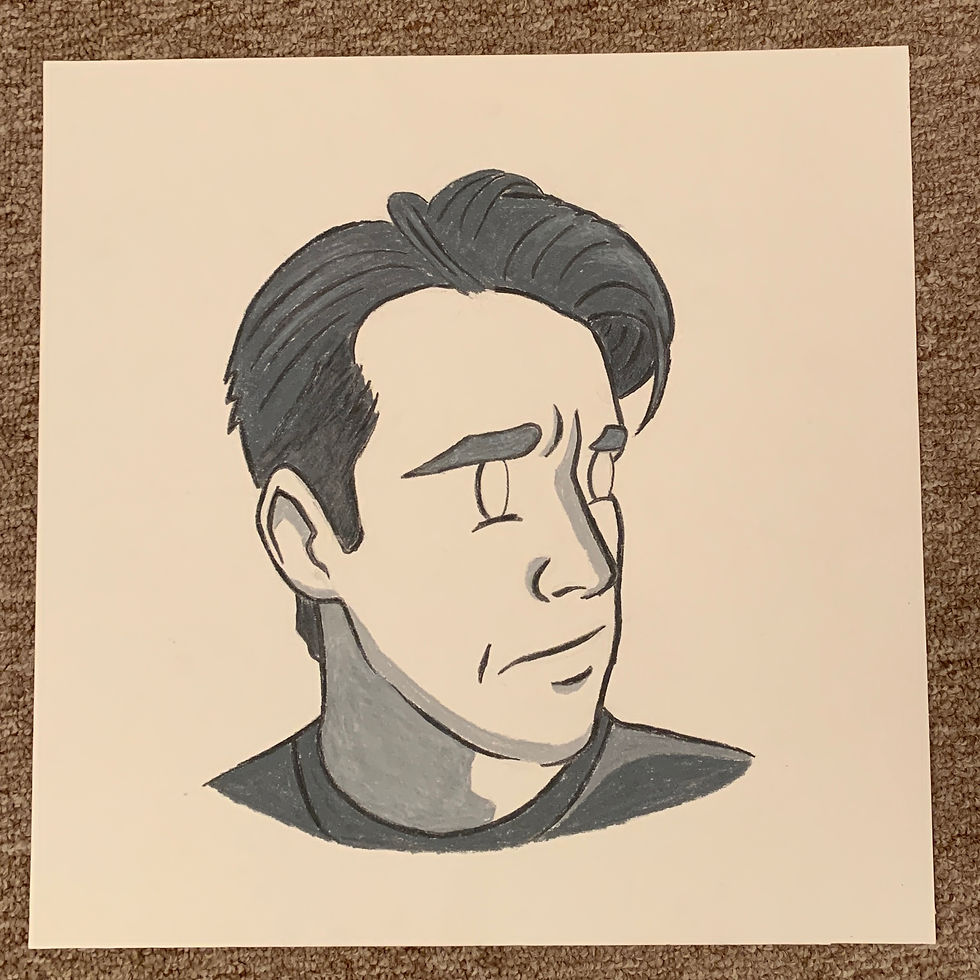

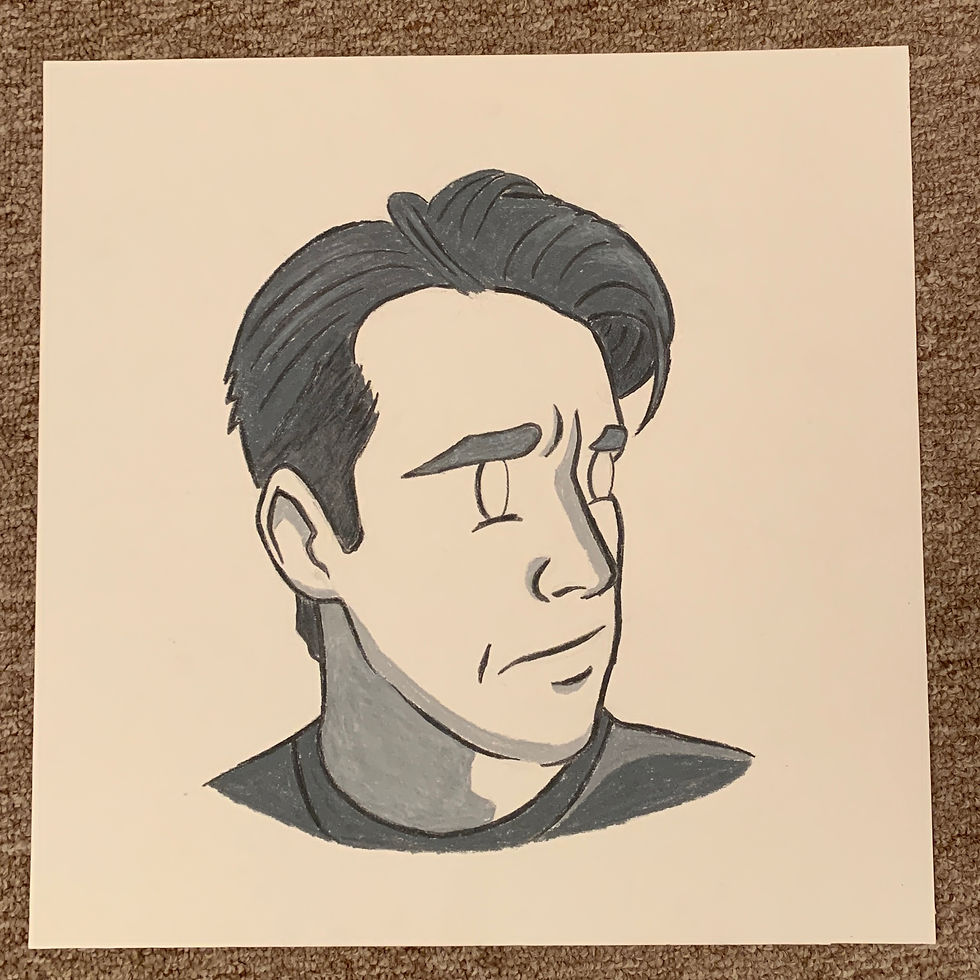

The NextGenET Device is a novel endotracheal tube concept that uses a series of soft baffles in place of the traditional balloon. An image of the NextGenET device and a traditional Barrel cuff is shown above. I joined the team in September 2022 after an initial prototype baffle design was created and I began working with the team on developing testing apparatuses for prototype verification testing.

Force Testing Rig Prototyping and Development

One of the first projects I worked on with Lauren Grice and G. Craig was ideating and prototyping a force testing rig to measure the pressure created by the baffles on a simulated trachea.

The primary ISO standard that provides standard ETT design and testing guidelines was ISO 5361:2016. This standard provides a test method for tracheal seal that requires the ETT balloon to be at a standardized pressure (27 hPa) to measure fluid leakage. This pressure value was also defined as the threshold before damage to the trachea from tracheal stenosis could occur.

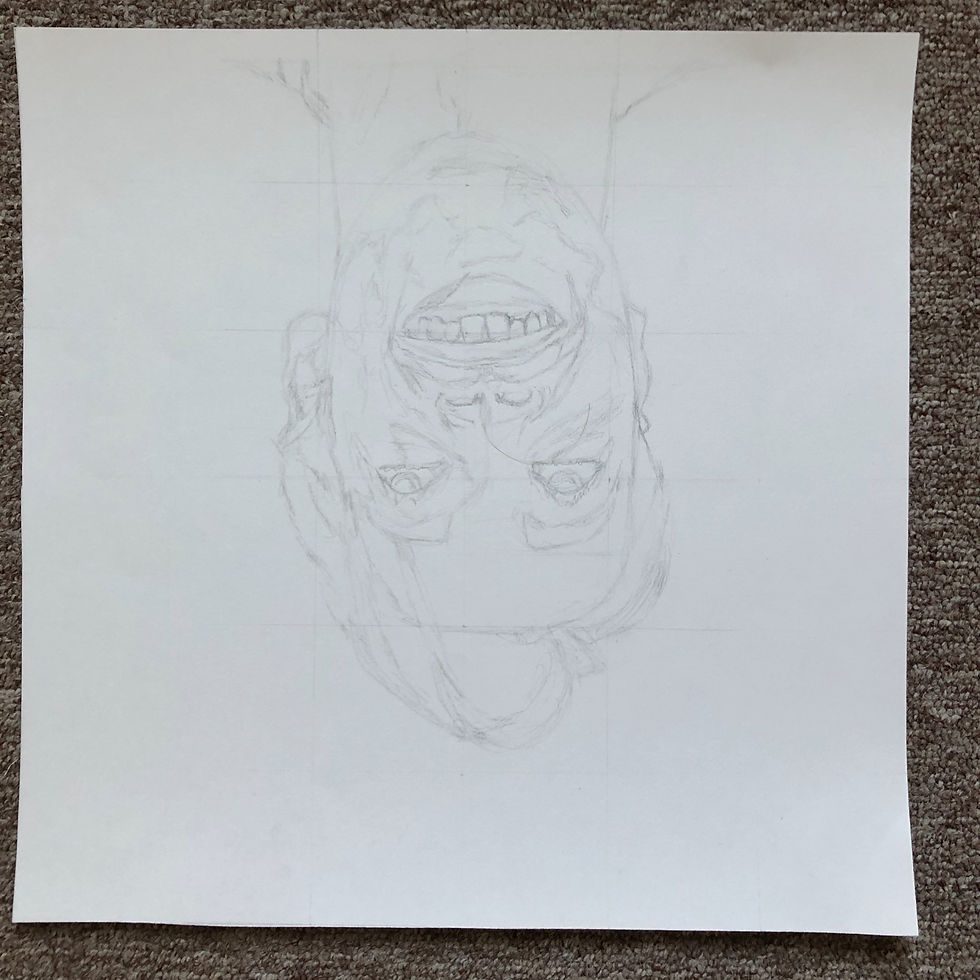

From September 2022 to November 2022, Lauren, G. Graig, and I met weekly to brainstorm, sketch, and prototype the force testing rig. The images shown to the right show the progression from concept sketches that I created to physical prototypes that we created to test.

This concept I created involved having many round pad FSR's concentrically placed in a cylindrical silicone sleeve. The ETT would be placed inside the cylindrical rig which would measure pressure exerted by the ETT at the 3, 6, 9, and 12 o'clock positions

This concept I sketched from discussions with G. Craig involved having two rectangular plates bead together by rods and a tightening bolt similar to a screw vice. Ideas for square, triangular, and octagonal rig cross sections were also conceptualized here. Tightening the bolts on the rig would compress the plates and would let us simulate a range of trachea diameters

Based on the sketch of idea 2, this force rig is comprised of foam plastic sheets screwed together with foam blocks in between to evenly distribute the clamping pressure. The ETT foes in the middle of the rig where the FSR is placed.

This concept I created involved having many round pad FSR's concentrically placed in a cylindrical silicone sleeve. The ETT would be placed inside the cylindrical rig which would measure pressure exerted by the ETT at the 3, 6, 9, and 12 o'clock positions

After the first prototype development, my contributions shifted towards education illustrations creation (which I had begun while working on the testing rig) and understanding the broad scope of regulatory testing requirements for the NextGenET device.

Educational Illustration Work

I then created a four panel illustration of the use procedure of the NextGenET Device. It is shown below. In addition to the still images, I also provided the Photoshop and Procreate files with instructions on how to turn on and off individual layers for modification of the illustration.

This is a sagittal cross section of a person. The enclosed larynx and trachea is displayed here.

This is a sagittal cross section of a person. The larynx and trachea are both visible here.

Once the baffles are past the glottis, they provide a more comprehensive seal preventing bacteria from entering the lungs.

This is a sagittal cross section of a person. The enclosed larynx and trachea is displayed here.

Initial Master Test Plan Development

During the end of my position with the NextGenET Team, I started the development of a Master Test Plan. This included proposed necessary tests compiled from relevant ISO Standards (mainly ISO 5361) which I thoroughly analyzed and synthesized into the Master Test Plan structure. Additional tests were added to the plan due to the proprietary cuff baffle design. In the test plan, I created equipment and supplies list for each test. Also, I created a list of other relevant references and ISO Standards that should be purchased later on in development. I also researched over a dozen 510(k)-summaries to understand other relevant testing standards. Lastly, I created a design specifications checklist sheet to show all design specs that need to be met as per ISO 5361 and our own requirements (related to baffle design).

After this task, I transitioned into a full time role with the University of Pittsburgh Healthy Home Laboratory in February 2023.